Reduction of Pollutants

Pürlin® sheets and pillowcases are 100% recycled, thus there is no laundering process, which eliminates the introduction of chemicals or other toxins into the local water supply.

Pürlin® products save precious water by significantly decreasing the amount of water required to manufacture, produce, and launder traditional cotton-based linens.

Made exclusively with man-made fibers, Pürlin® linens are substantially more water efficient and ecologically sound than their cotton-based equivalents. Cotton is the most water-intensive of all crops, and the most toxic. Because cotton plants are vulnerable to insects and diseases in the field, numerous toxic pesticides and chemicals (including known carcinogens) are applied to the crops to prevent them from being destroyed.

Pürlin® sheets and pillowcases are 100% recycled, thus there is no laundering process, which eliminates the introduction of chemicals or other toxins into the local water supply.

Man-made fiber-based fabrics eliminate exposure to the toxic pesticides and chemicals required to properly grow and manufacture cotton.

Pürlin® reduces water consumption needed in both linen production and laundering, thus creating an immediate savings when compared to the use of traditional cotton-based sheets.

Pürlin® linen production saves tremendous amounts of water when compared to the manufacturing of traditional cotton-based linens.

2800 gallons of water are required to manufacture and produce one queen-sized cotton-based sheet; however, less than one gallon of water is required to produce an equivalent Pürlin® sheet set. When applied to scale of a 100-room hotel or hospital, more than 3.5M gallons of water are required to manufacture the facility’s standard 3-par cotton-based sheet and pillowcase inventory, and this is before considering the impact of repeatedly laundering these linens. Comparatively, an equivalent 3-par Pürlin® inventory requires just 980 gallons of water – period.

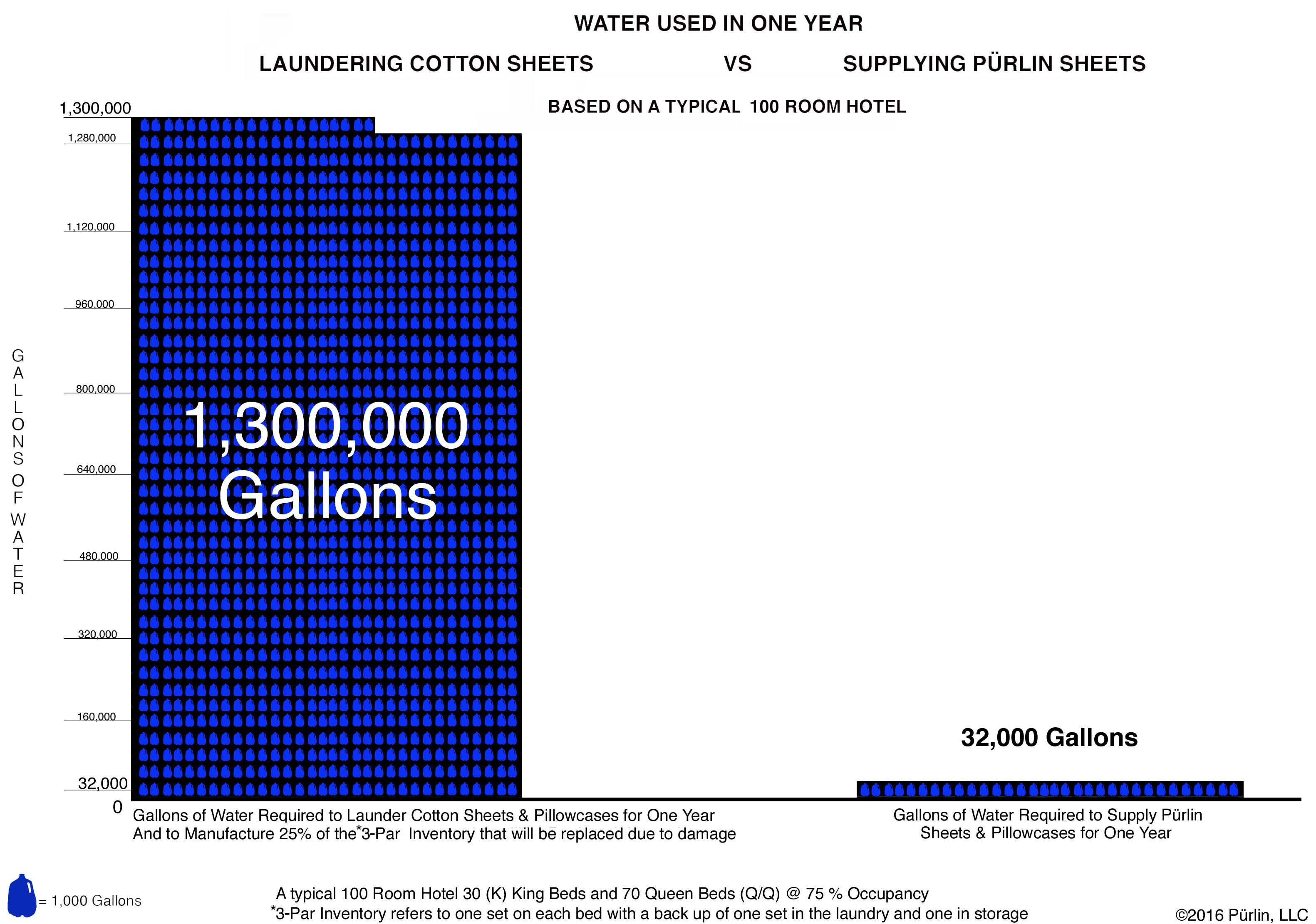

Once outfitted with stock, this same 100-room facility will use 400,000 gallons of water annually to launder their cotton-based sheets and another 900,000 gallons of water to manufacture the 25% replacement inventory that is typically required from lost or damaged linen each year. This equates to nearly 1.3M total gallons of water to maintain traditional cotton-based sheets in a 100-room facility.

In comparison, approximately 32,000 gallons of water are required to produce, recycle, and reconstitute Pürlin® linens necessary to supply the 100-room facility for an entire year.

Pürlin® linens are recycled through a heat-intensive melting process that reaches temperatures of ~510ºF. This heat exposure destroys bacteria and eliminates the need for powerful cleansing and sanitizing detergents, bleaches, or chemicals that are required in conventional laundering operations.

These toxic laundering chemicals can irritate sensitive skin, but more importantly, are discharged into the local wastewater treatment system through the wash-rinse cycle, ultimately reaching and negatively impacting the environment.

“If laid end-to-end, bed linens condemned by the world’s leading hotel chains in one year would go around the world more than twice. ”

Andy Marks, Founder and CEO of Sleeping Bags, a British Social Enterprise that creates products from end-of-life hospitality textiles.